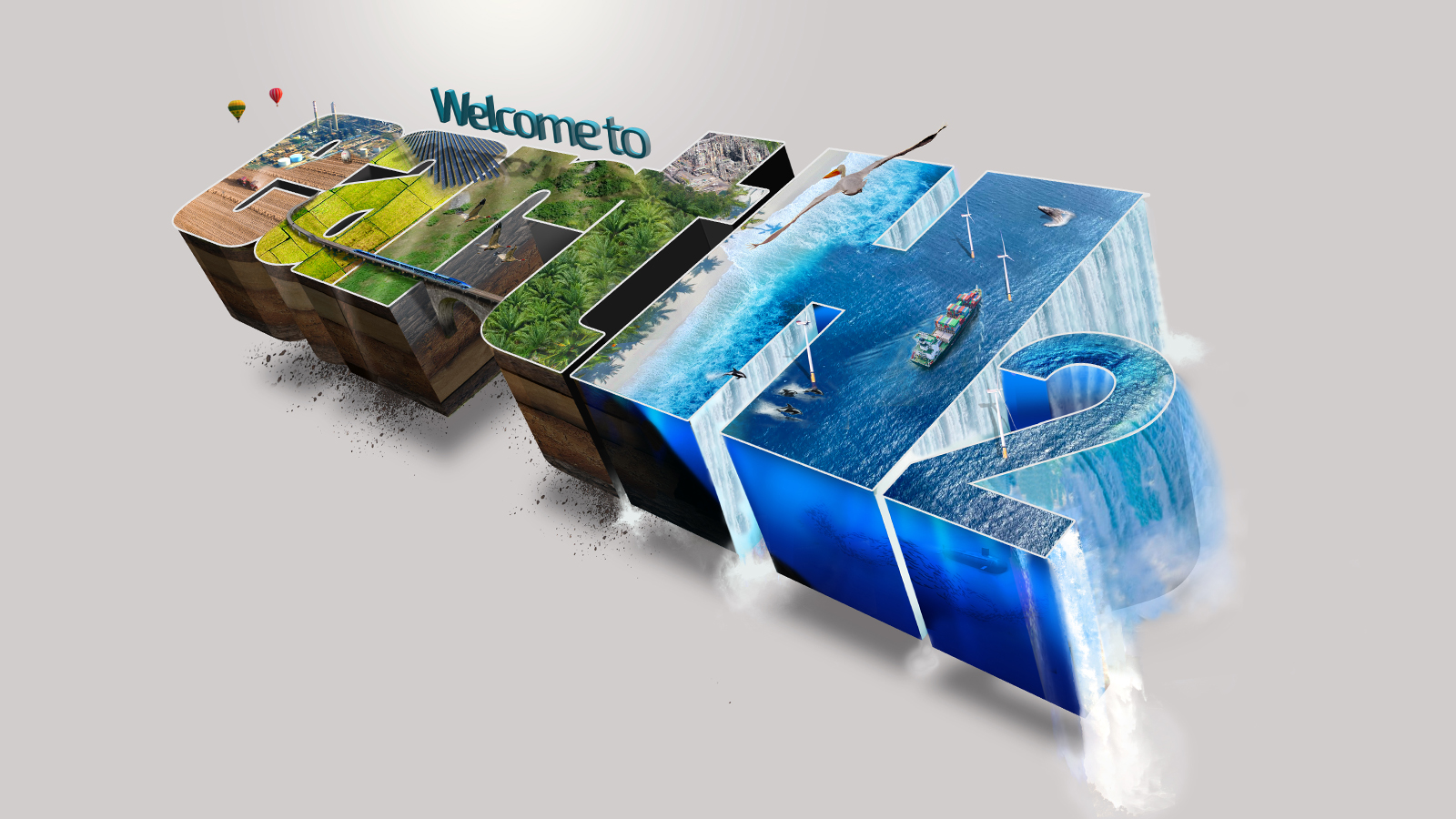

The energy transition consists of no longer using oil-based sources to produce energy, instead relying on sun, wind and agricultural residue based sources, and the development of new plant technologies to produce the materials and products that we use in our daily lives, by using raw materials and energy sources that are not derived from oil. The energy transition is also a new economic model, one that shifts from a linear (produce/consume/dispose) model to a circular one (produce/consume/recycle/reproduce), by using materials and substances obtained through recycling and designing products in order to extend their life and increase their circularity potential.

The energy transition, meaning the gradual shift to an economic, manufacturing and life system based on the non-wasting of resources and decarbonisation achieved through the increasing use of renewable resources with a low climate impact, has three prongs: the production of renewable energy, the production of materials and products with a decreasing carbon footprint achieved through new plant technologies, and waste recycling. Waste recycling allows to produce new materials and new substances that have a lower environmental impact compared to those that use virgin raw materials, as they save resources by reusing existing ones; the materials and substances produced through recycling can then be used again in the goods manufacturing and energy and chemical industries, thereby improving the overall environmental impact.

Il modello che ha sviluppato NextChem è una piattaforma tecnologica e industriale “circolare”, che include in modo integrato questi tre ambiti della transizione energetica: il riciclo della plastica per produrre nuovi materiali riciclati e con minore impatto carbonico da usare nell’industria per la produzione di oggetti, il riciclo chimico dei rifiuti di plastica e secchi non recuperabili in altro modo per produrre sostanze chimiche e carburanti “circolari” con minore impatto carbonico da usare per la mobilità sostenibile e per tante produzioni industriali, e la produzione di idrogeno verde da energie rinnovabili, che può essere utilizzato per esempio per la mobilità sostenibile. Nel nostro modello puntiamo ad avere una neutralità carbonica, ovvero a far sì che le emissioni di CO2 prodotte dagli impianti di riciclo vengano ampiamente compensate con la CO2 risparmiata avendo evitato l’incenerimento dei rifiuti e con la CO2 che si risparmierà impiegando i prodotti “circolari” al posto di quelli derivanti dalle fonti fossili, come il petrolio e il gas naturale. Nel nostro modello puntiamo anche ad avere “rifiuti zero”, ovvero a far sì che quanto esce, in termini di scarti, dai processi di riciclo, sia una percentuale costantemente decrescente e tendente allo zero.

A model of this type is the model of the future, but we can start creating it today. It is already possible to create green circular districts with these characteristics, technologies and ambitions.